Stamped Concrete Installation Tips

Spring offers moderate temperatures ideal for stamped concrete application, ensuring proper curing and durability.

Summer provides consistent warm weather, but high temperatures require careful timing to prevent rapid drying.

Fall's mild temperatures and lower humidity levels create optimal conditions for stamping and curing.

Ways to make Stamped Concrete Service work in tight or awkward layouts.

Popular materials for Stamped Concrete Service and why they hold up over time.

Simple add-ons that improve Stamped Concrete Service without blowing the budget.

High-end options that actually feel worth it for Stamped Concrete Service.

Finishes and colors that play nicely with Stamped Concrete Service.

Stamped concrete service involves creating decorative patterns and textures on concrete surfaces, offering an aesthetic alternative to traditional paving options. This process enhances the visual appeal of driveways, patios, and walkways, with customization options including colors, patterns, and finishes. Proper timing ensures the concrete sets correctly, preventing issues such as cracking or surface imperfections. The optimal temperature range for stamped concrete application is generally between 50 and 85 degrees Fahrenheit, with lower humidity levels supporting better curing conditions.

Statistics indicate that stamped concrete can last for decades when installed during suitable weather conditions, with proper maintenance extending its lifespan further. The process is popular due to its versatility and cost-effectiveness compared to natural stone or pavers. Planning installations during moderate seasons helps ensure a smooth curing process, resulting in a durable and visually appealing surface.

Avoid extreme cold or heat to ensure proper curing and adhesion of stamped patterns.

High humidity can delay curing, while low humidity speeds it up, affecting the final finish.

Spring and fall are generally ideal for stamped concrete installation due to favorable weather.

Proper surface preparation and timing are crucial for achieving the best results.

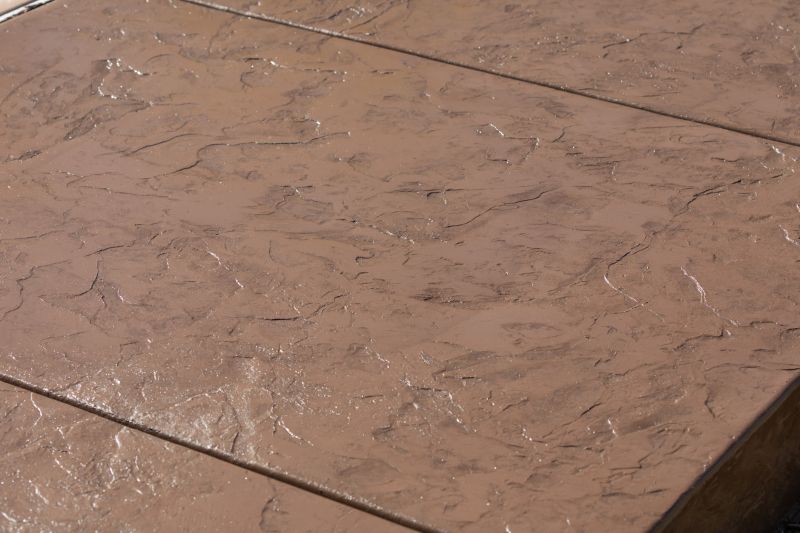

A decorative pattern on a concrete driveway.

Enhanced with multiple colors for a natural stone look.

Stamped concrete used for outdoor patio areas.

A textured surface providing both style and slip resistance.

Color added during the pour for vibrant, long-lasting hues.

Tools pressed into fresh concrete to create intricate designs.

A protective sealant enhances durability and appearance.

Decorative borders framing a driveway or patio.

| Season | Optimal Conditions |

|---|---|

| Spring | Moderate temperatures and lower humidity support curing. |

| Summer | Consistent warm weather, avoid peak heat hours. |

| Fall | Mild temperatures and lower humidity levels. |

| Winter | Not recommended due to freezing temperatures. |

| Early Morning | Ideal for cooler seasons to avoid midday heat. |

| Late Afternoon | Suitable when temperatures are stable. |

| Rainy Days | Avoid scheduling during rain to prevent surface issues. |

Scheduling stamped concrete services during the right season maximizes the quality and longevity of the installation. Proper timing allows the concrete to cure correctly, reducing the risk of surface imperfections and cracking. Consulting with experienced contractors can help determine the best window based on local climate conditions.

A beautifully stamped patio with vibrant colors.

A worker stamping a pattern into fresh concrete.

Multiple colors blended for a natural stone appearance.

Little measurements that prevent headaches on Stamped Concrete Service day.

A 60-second routine that keeps Stamped Concrete Service looking new.

A frequent mistake in Stamped Concrete Service and how to dodge it.

Small tweaks to make Stamped Concrete Service safer and easier to use.

Lower-waste or water-saving choices for Stamped Concrete Service.

Interested parties are encouraged to contact for more information or to schedule an assessment. Proper planning and timing can ensure a durable, attractive stamped concrete surface that enhances the property's aesthetic appeal.